![]()

SilverWorksIII

(Sold Out!)

Saturday, May 26th, 2001

10:00-12:00noon: Brunch

Refreshments will be available in the workshop throughout the demonstration.

12:00-3:00pm: Reticulation with SAS Artisan Paulette Myers

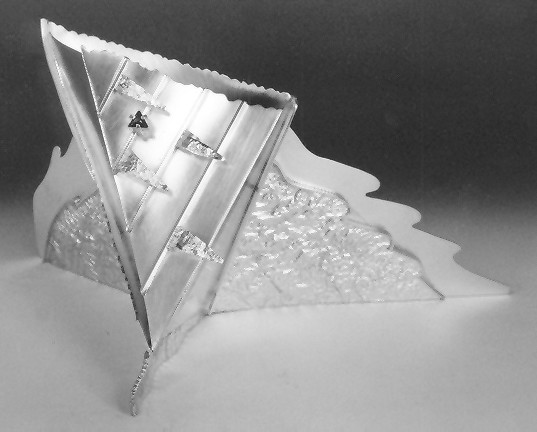

Vessel by Myers–reticulation silver, sterling, pink tourmalineReticulation is a heat induced texturing process of sheet metal, utilizing specific natural properties of the silver alloy #820. Myers will demonstrate how the fluid relief pattern can be accomplished through an oxide protective skin build-up followed by localized liquification of the encased sheet metal in a row-pattened method. She will demonstrate how and why reticule formation can be controlled to offer delicate and fine relief-pattening to deeper and more broad linear structure. She will also form the reticulated sheet.

Myers will present her latest reticulation pursuits involving roll-printing and forming. The malleability of reticulated silver sheet is excellent in hydraulic press application, die forming and hand forming.

This process lends itself to the application of vessels, serving utensils, sculpture, and jewelry. It has new and progressive applications in creativity and invention.

Paulette Myers, Professor of Metalsmithing at Southern Illinois University, Edwardsville, IL, is well known for her expertise in reticulation. Since 1971 she has pursued the process with the #820 silver alloy as well as copper alloys, nickel alloys and gold. She has utilized reticulation in holloware and jewelry exemplifying the qualities of this technique. As early as 1972 she received recognition of honorable mention in Hollowware in the Student Sterling Competition. She pursued her thesis in 1971-73 at Washington University, St. Louis, MO in the research study of reticulation with 13 different alloys. Following that study, she discovered and developed perforation of nickel silver. That metal phenomenon is published in the Metalsmiths Papers of the Sociely of North American Goldsmiths 1981 and was presented at the Society of American Goldsmiths Convention, Tucson, AZ in 1980. Paulette sees the field of metal as a goldmine of endless undiscovered techniques and processes waiting to be discovered and developed.

The demo will cover:

820 silver alloy

Thickness of sheet 24 gauge vs. thicker or thinner

- Precut desired pattern of sheet metal: pros/cons prior to torch process.

- Oxide build-up process

What is it and what is its function

Variable factor of examples of 3-5 oxide layers and why

- Reticulation

Torch type variable N/G + Compressed air; N/G + OXY, propane + OXY, acetylene prestolite torch

Torch flame type; size of flame vs. width of row

Placement of rows for design control

Partial sheet reticulation and why

- Forming options - Reticulation does not need to stay flat.

Flexibility and malleability

When to anneal

Edge definition

What mallets to use

- Soldering factors

- Application of silver alloy reticulation to hollowware, sculpture and jewelry

- Surface Finishes

3:00-3:30pm: Break for Other Activities

Receive a free coffee spoon and piece of sheet of the NEW firestain-free Argentium sterling developed by British silversmith Peter Johns.

- Providence File Co. will have a wide assortment of high quality files available at wholesale prices.

- Receive Jeff Herman’s updated Silver Care Guide and come prepared with silver care and restoration questions for him.

3:30-6:30pm: Reticulation Demonstration Continues

6:45pm: Dinner & presentation of the second Hans Christensen Sterling Silversmith Award

Cost

$75 (Non-Members)

$60 (Current SAS Members)

Payment Due Date

Your non-refundable payment is due May 12, 2001. Limited to 30 people. Confirmation and directions to SAS will be mailed to you.

Questions

E-mail SilverWorks

401/567-7800 (8:00am-8:00pm EST)

Back

to SilverWorks Info. Page

Back

to Silver Events

Back

to Home Page